November 18, 2022

Extending the life of our deteriorating sewer & drainage systems

Written by: AK

Extending the usable life of deteriorating drains infrastructure

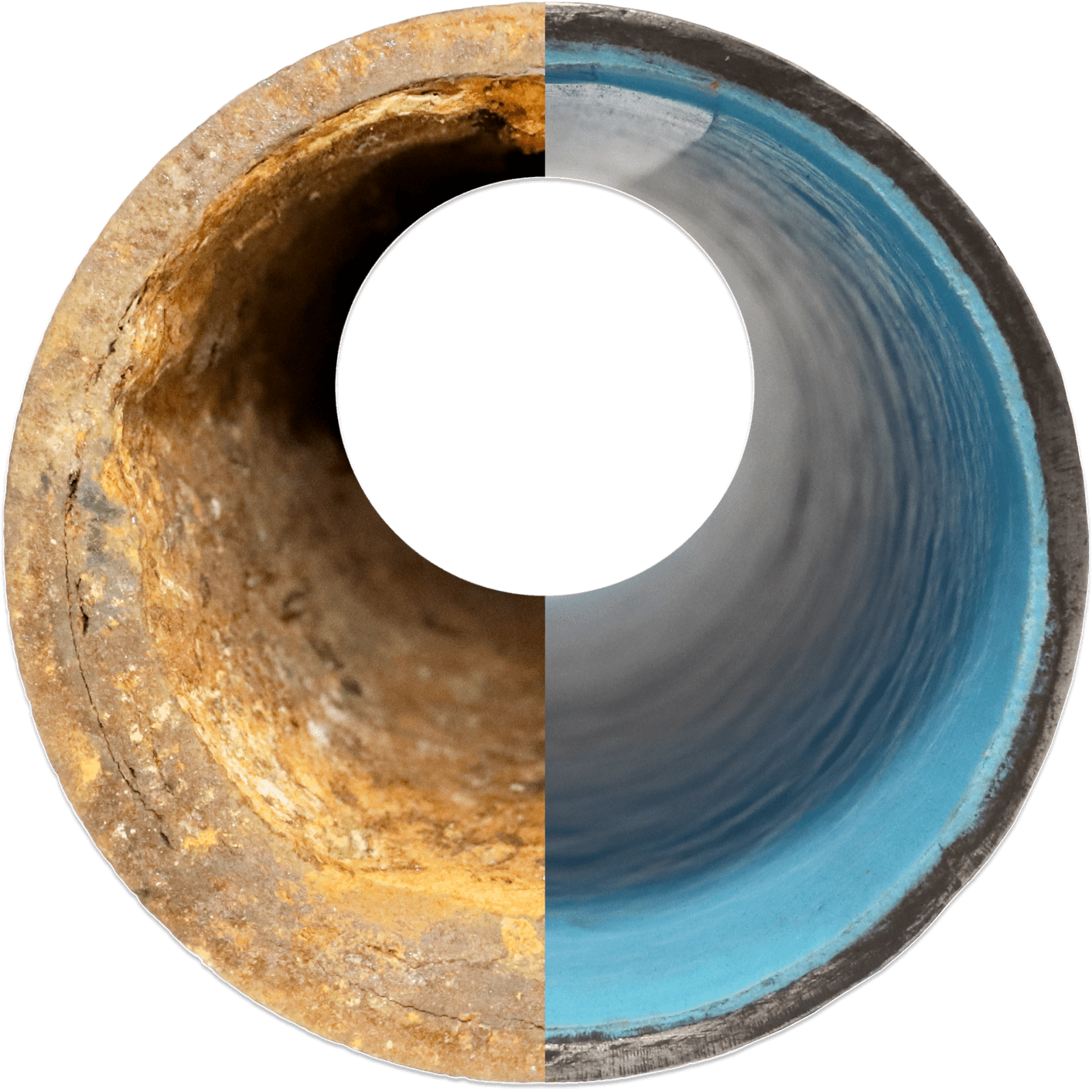

Spray-in-place pipe rehabilitation is the new generation method for rehabilitating sewer & drain piping.

Spray-in-place pipe rehabilitation is a method of repairing damaged or deteriorating drain pipes without the need to dig them up and replace them. It involves spraying a special epoxy coating onto the interior walls of the pipe, which forms a durable, watertight seal that restores the structural integrity of the pipe. This method is less invasive and less disruptive than traditional pipe replacement and can be completed in a shorter amount of time.

Deteriorating sewer & drain infrastructure is a global problem. Old piping systems built out of cast iron, orangeburg pipes, clay, and even PVC plastics are breaking down, causing massive issues for building health.

Due to this deterioration, the problems arising from these structural failures are causing water damages and other structural issues for buildings. Sewer & drain networks are leaking waste into soil, causing damage to water supplies and nature in general.

As wastewater isn’t contained inside the very systems designed to transport it, it is also causing health & safety issues as wastewater contains several different types of viruses and bacteria harmful to the environment, humans, and animals.

In addition to the expensive and consuming traditional methods of replacing the broken pipes, there are several technologies that makes it possible to rehabilitate these pipes without digging them up or tearing them out of the walls and ceilings inside buildings.

Modern technology allows us to thoroughly clean the pipes from within through solutions like high-pressure water jetting and mechanical descaling and cleaning with various tools such as drain cleaning chains operated with flexible shafts.

Once cleaned and thoroughly inspected, the piping systems can then be renovated with various different methods such as pipe lining the whole piping system, partial repairs through connection lining and patch lining, or by coating the damaged pipes from within with Spray-in-place coating (SIPP).

That’s Spraypoxy’s area of specialty – the coating process. For over a decade, we’ve been developing equipment and materials for an efficient and economically sound way of coating the drainage systems from within with 100% solids epoxy resins and our proprietary high pressure spray coating equipment.

Drain cleaning is the process of removing debris and blockages from plumbing pipes and drains. This is typically done using specialized tools, such as a drain snake or hydro jet, to break up or flush out the blockage. Drain cleaning is important to prevent clogs and backups in plumbing systems, which can cause water damage and other problems. It is also important for maintaining the overall health and efficiency of the plumbing system.

There are several reasons why drain pipes may be coated. One reason is to prevent corrosion and deterioration of the pipes. Over time, drain pipes can become corroded and weakened, which can cause leaks or even complete failure of the plumbing system. Coating the pipes can provide an additional layer of protection against corrosion, helping to extend their lifespan and prevent costly repairs.

Another reason for coating drain pipes is to improve their flow capacity. Over time, the interior walls of drain pipes can become rough and uneven due to mineral deposits and other debris. This can cause a reduction in flow capacity, which can lead to clogs and other problems. Coating the pipes can create a smooth, uniform surface that allows water and other materials to flow more easily, improving the overall efficiency of the plumbing system.

Finally, coating drain pipes can also help to prevent the growth of bacteria and other microorganisms. These organisms can thrive in the moist, dark environment of drain pipes, and can cause unpleasant odors and even health problems if they are not controlled. Coating the pipes can create a barrier that prevents the growth of these organisms, helping to keep the plumbing system clean and healthy.

As the market size for Sewer & Pipeline Rehabilitation industry, just in the US, is around 13 billion dollars (according to IBIS) with over 7600 businesses working in the industry employing more than 100000 people, the possibilities are endless for new players in the market.

There has never been a better time to jumpstart a new sector in your plumbing business offering your customers professional drain inspection, cleaning & coating services – or if you don’t have an existing business, the time is just as right for setting up a new company and start solving the wastewater problems that are already available, everywhere around you.

Drain, sewer & rainwater system problems occur in all types of buildings and facilities, such as multi-apartment residential buildings, factories, commercial properties, office buildings, and domestic houses.

As the deteriorating sewage systems impose an immediate threat to health and safety of the occupants as well as the structural condition of the building, these problems need to be fixed before the whole world drowns in s… Wastewater.

If you’re interested in learning more about the issue or about how spray-in-place pipe rehabilitation and Spraypoxy can help you, don’t hesitate to contact us – we’re here to help!

Interested in learning more about how spray-in-place pipe rehabilitation works? Don’t hesitate to contact us - we’re here to help!